- Inspire

- Innovate

- Integrate

- Home

- Who we are

- Services

- Portfolio

- Training

Green Building Credential Courses

Classroom Courses NewLEED Green AssociateLEED AP BD+C Certification Training in Saudi ArabiaOnline Courses NewLEED Green Associate Exam Preparation CourseLEED AP BD+C Exam Preparation CourseIGBC AP Made Easy – Online Exam Preparation CourseCourse Materials NewLEED V4 AP BD C Made EasyLEED Green Associate Made Easy V4Energy Modeling & Simulation CourseLEED and IGBC Exam Preparation – Q&A forum NewEngineering Courses

- Robotics -for Little Engineers New

- MEP Engineering Training Course Qatar New

- Fire Fighting New

- Plumbing Training Course with Certification New

- Heating Ventilation & Air-conditioning New

- 3D laser Scanning Training Course Qatar New

- Plumbing & Fire Fighting

- Electrical Design Course

- Piping Design Engineering Training Course

- Piping Design course – Piping Simulation Analysis Training

- Energy Modeling & Simulation Course

- Blog

- Careers

- Contact Us

- Home

- Infrared Thermography Services

Infrared Thermography Services

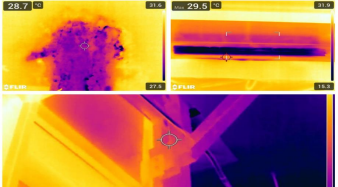

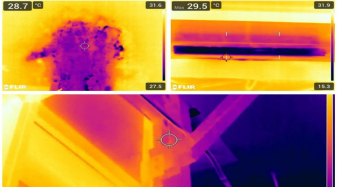

Infrared thermography, also known as thermal imaging, is a cutting-edge technology that allows us to see and understand the world in a whole new light—literally. This non-invasive technique uses infrared radiation to capture temperature variations in objects, structures, and living organisms. Whether you’re a professional in the fields of building inspection, electrical maintenance, mechanical maintenance, or simply curious about this fascinating technology, you’ve come to the right place.

Infrared thermography, also known as thermal imaging, is a cutting-edge technology that allows us to see and understand the world in a whole new light—literally. This non-invasive technique uses infrared radiation to capture temperature variations in objects, structures, and living organisms. Whether you’re a professional in the fields of building inspection, electrical maintenance, mechanical maintenance, or simply curious about this fascinating technology, you’ve come to the right place.

What is Infrared Thermography?

Infrared thermography is the art and science of capturing and interpreting infrared radiation emitted by objects and surface Infrared/thermal testing is a non-destructive testing (NDT) that involves the use of temperature and heat flow measurement as a means to predict or diagnose failure. By using specialized cameras and equipment, we can detect and visualize these thermal emissions, creating images and data that reveal hidden insights about the thermal behavior of the subject.

Applications of Infrared Thermography

Building Inspection

Infrared thermography is a valuable tool for building inspections. It can help identify issues such as: • Heat Loss: Detecting areas of heat loss in buildings, helping homeowners and businesses improve energy efficiency.

- Moisture Intrusion: Locating sources of water damage or leaks, which is essential for preventing structural damage and mold growth. - Electrical Problems: Identifying overheating electrical components before they fail, reducing the risk of fires and equipment damage.

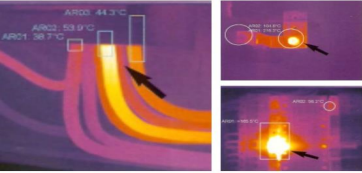

Electrical maintenance

In the realm of electrical maintenance, thermal imaging can be a game-changer:

- Fault Detection: Detecting overheating electrical components, such as faulty connections or failing equipment, before they lead to costly downtime. - Predictive Maintenance: Implementing predictive maintenance strategies to increase the lifespan of electrical systems and reduce operational costs.

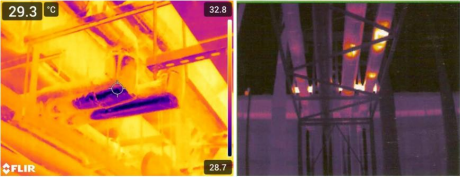

Mechanical maintenance

In the realm of electrical maintenance, thermal imaging can be a game-changer:

- Fault Detection: Detecting overheating electrical components, such as faulty connections or failing equipment, before they lead to costly downtime. - Predictive Maintenance: Implementing predictive maintenance strategies to increase the lifespan of electrical systems and reduce operational costs.

Oil & Gas Thermography

1- Gas Leak Detection: Infrared cameras can detect fugitive gas emissions and leaks in pipelines and storage tanks, allowing for rapid response and preventing environmental hazards. 2- Steam Systems: It is used to identify steam leaks and insulation defects in steam systems, ensuring energy efficiency and safety. 3- Tank Level Monitoring: Infrared thermography can be used to monitor the level of liquids in storage tanks by detecting the temperature differences between the liquid and the vapour space. 4- Heat Exchanger Inspection: Infrared thermography is employed to assess the performance of heat exchangers by detecting fouling, scaling, or blockages within the tubes.

Why Choose Infrared Thermography?

Infrared thermography offers numerous advantages

Versatile

It’s applications span across multiple industries, from construction to healthcare.

Precise

It provides accurate temperature measurements, enabling early detection of issues.

Efficient

It allows for rapid inspections, reducing downtime and costs.

Non-Destructive

It doesn't require physical contact with the subject, making it non-invasive and safe. precision.

Frequently Asked Questions

FAQ's

Thermography is a technique that uses infrared radiation (heat) to create images of objects. It works by detecting the infrared radiation emitted by objects and converting it into a visual image. The different colours in the image represent different temperatures.

Yes, thermography is a safe technique that does not require physical contact with the object being inspected. It is a non-invasive and non-contact method.

Yes, there are some limitations to thermography. One limitation is that it requires line-of-sight. This means that the object being inspected must be visible to the thermal camera. Another limitation is that environmental conditions can affect the accuracy of thermography results. For example, rain or snow can obscure the thermal image. Finally, thermography cannot detect temperature variations that are too deep below the surface of an object.

Yes, proper training is essential to use thermography equipment effectively and accurately interpret thermal images. There are certifications available for handling the thermography equipment and carrying out thermography inspections.

The cost of thermography equipment can vary, but it has become more accessible over the years. The benefits of early detection and cost savings often justify the investment.

Get in Touch

Have Any Other Questions?

Subscribe

Get latest news & events details

Quick Links

+1 (832) 475-9130

+44 0786 7249154

+91 73059 60692

+91 96772 63895

+65 8709 8733

+966 55 720 9522

+974 44427968

+971 45657706

Copyrights © 2025. Conserve Solutions. All Rights Reserved.