Conserve was invited by the Client (MEP contractor of a prestigious health care facility) to provide engineering solution for hydro test failed piping system in the chilled water system of the district cooling plant. The client requirement is to conduct the stress analysis for hydro test failed (supports pulled out from base) chilled water piping system inside the tunnel.

The constraints in the existing piping system are

- Locations and types of supports cannot be changed.

- Bellows and Anchor support cannot be replaced/relocated.

The following observations were made in our initial study,

- High load impact on anchor in previous support configuration.

- Support configuration not designed for thermal & hydro loading.

- Bellow thrust force + thermal force + friction force on anchor.

- Piping support designed based on site experience.

- Stress analysis not performed.

The following software tools are used for analysis,

- Stress Analysis Software – CAESAR II.

- Structure analysis Software – Staad Pro.

The following recommendations were made to qualify the system by carrying out stress & structural analysis,

- Support structures are redesigned with existing configuration and implemented to qualify system failure.

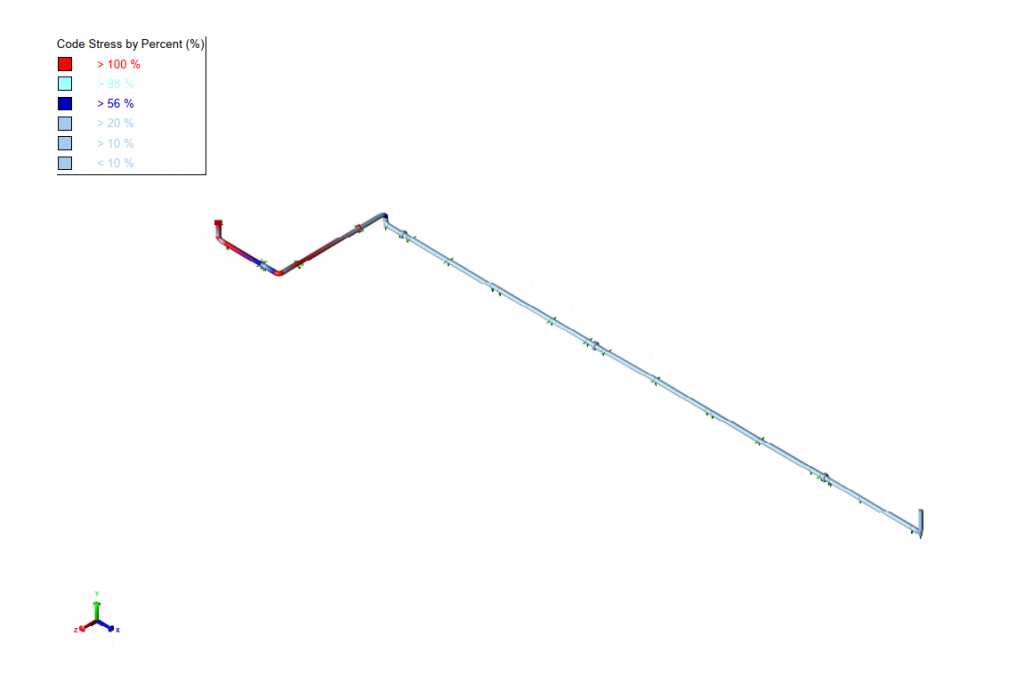

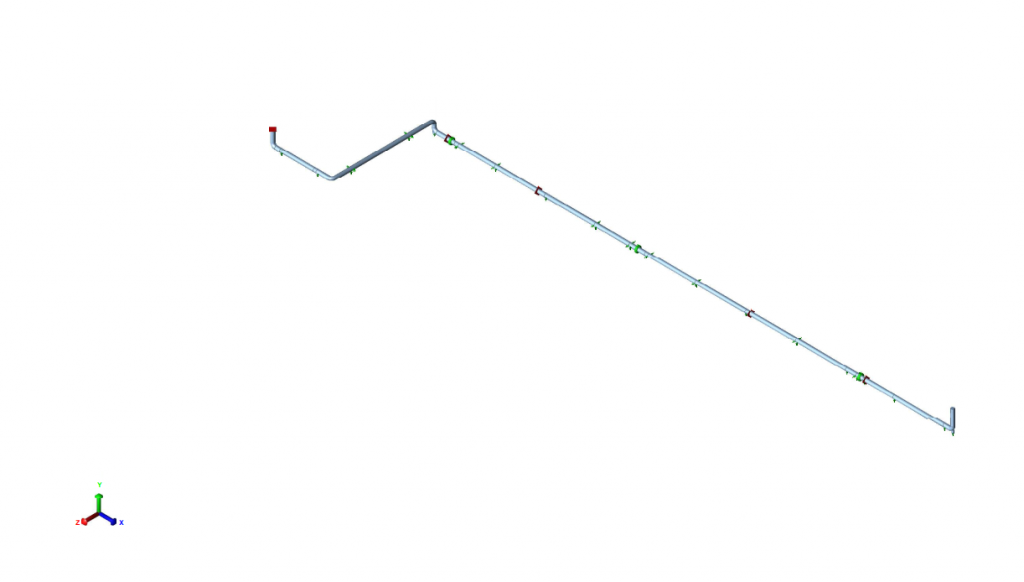

- The system is assessed for max forces and moment for both supply and return line and after analysis, recommendation is found to be safe.

- Limit rods are designed to absorb the pressure thrust of the expansion joint in case of anchor failure.

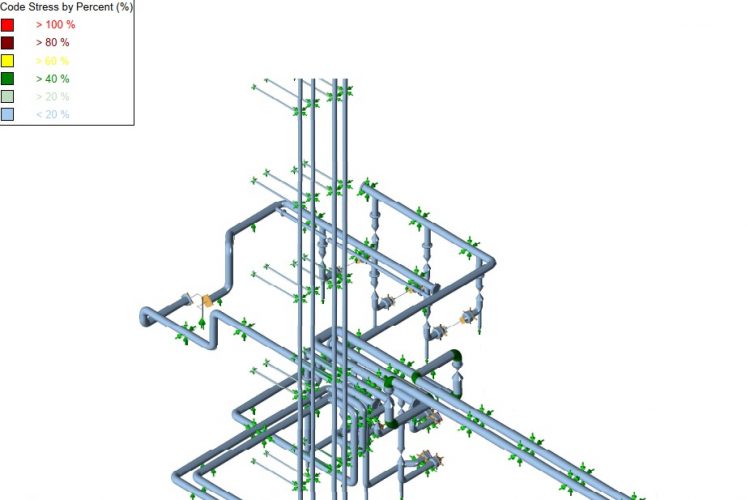

Before Recommendation

After Recommendation

Conclusion

The project team have designed the piping support based on their experience, however behaviour of hydro-thermal systems operating at high pressure cannot be predicted only by experience. It is always recommended to comply with the codes and standards following our recommendations.

- Stress & structural analysis should be conducted to avoid such failures.

- Stress analysis has to be performed in design stage itself and structural analysis to be performed based on stress analysis output loads to avoid last minute failure.

Conserve Solutions will be happy to assist your projects. Our offices are located in India, UAE, Qatar, Saudi Arabia, Canada, United Kingdom, Egypt and Singapore.

Author

Bazeeth Ahamed K M

Mr. K M Bazeeth Ahamed is an USGBC LEED Faculty & consultant in Green Buildings. He has completed his Post Graduation in Mechanical Engineering from Birla Institute of Technology in 2002 and has spent 12 years in Academics, Research, MEP Contracting, Energy Audits and Green Building Consultancy.