This presentation is prepared as a part of our internal knowledge sharing sessions based on a Duke University programme, “Oil & Gas Industry Operations and Markets” offered through Coursera. The course is well structured and explained by Lincoln Preston in a way, even a beginner to the industry will obtain a clear picture and knowledge of the fundamentals. I have tried summarizing my understanding from the course and I believe would be an interesting read for someone who is trying to gain basic knowledge about the Oil & Natural Gas Industry.

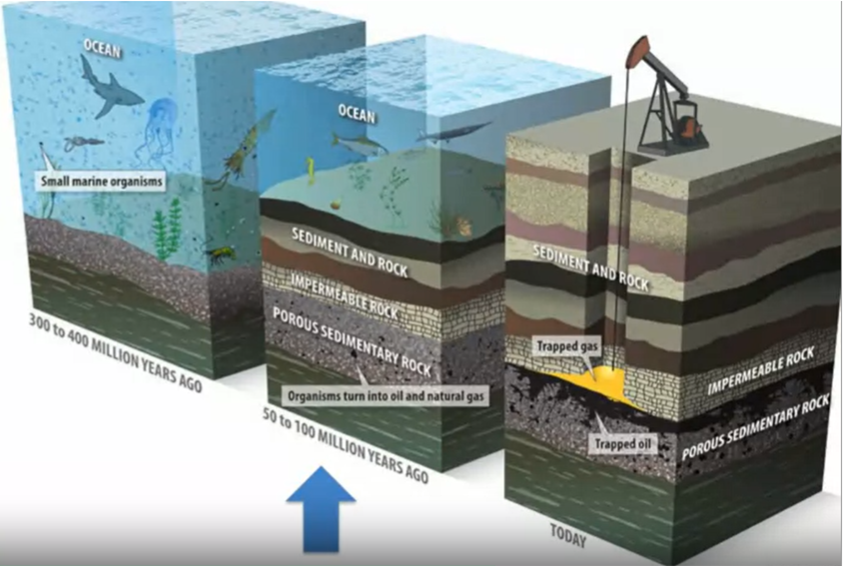

Sources – Sedimentation of Microscopic Marine Organisms

Cost of Oil per barrel today in the Middle East defines the cost of basic food supplies in my hometown, which is located in the Southern India! Oil & Gas industry being a functional decider of costs and operations of all related markets in the world as on date, ever wondered What is the source of Oil & Natural Gas?

Planktons!!!

Sedimentation of dead microscopic marine organisms through millions and millions of years, especially in the off-shore region compressed by eroded soil from the land is the birthplace for Oil & Natural Gas.

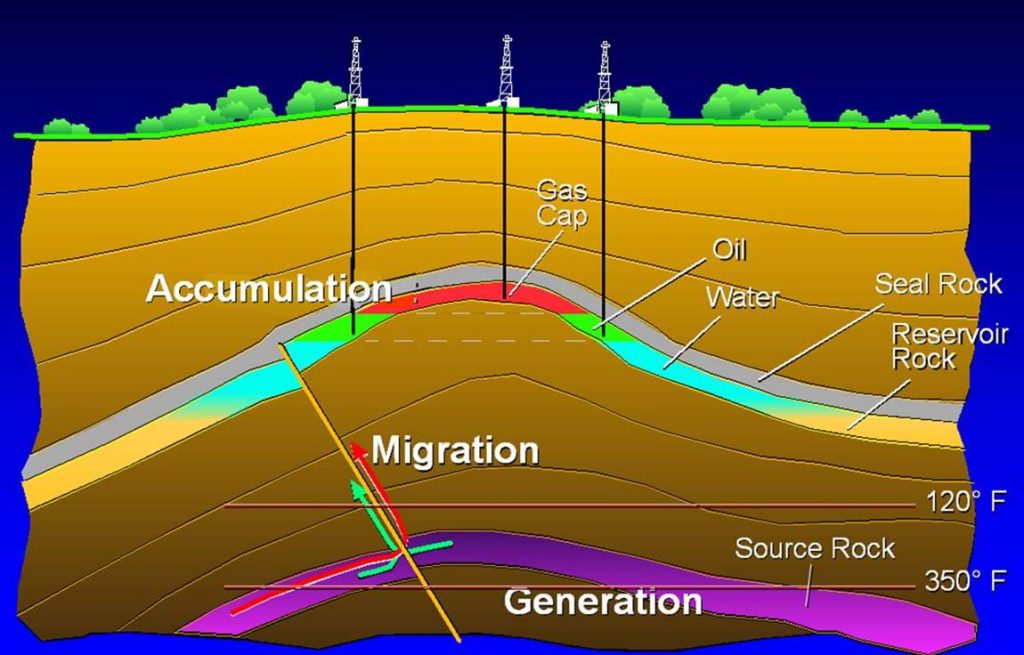

The Hydrocarbon System

- Source Rock

- Thermal Maturation

- Migration Pathway

- Reservoir Rock

- Cap Rock

- Geological Trap

Dead microorganisms and sediments eroded from the land lying under the seabed for millions of years, would end up creating Oil & Natural Gas?!

No, Nature is even more complicated and interesting than we think. It requires coexistence of 6 components of nature to create a geological system capable of producing Oil & Natural Gas. They call it, “The Hydro-Carbon System”. The components are,

- Source Rock: Layers of rock with sediments rich in organic content

- Thermal Maturation: As years roll, eroded sediments keep deposited over the source rock compressing it to the depths. Combustion of source rock into Oil & Natural gas happens specifically within a depth of 2-5 Kilometers (approximately) with temperature ranges between 60 C and 160 C, otherwise called as Oil Window.

- Migration Pathway: Drilling to the depth of source rock with the available technologies is not very economic for the mineral rights holder (generally Governments) or the investors. Hence, a successful hydrocarbon system would have a migration pathway where the produced Oil & Natural gas travels through a geological crack/pathway and stored in a layer called Reservoir rock.

- Reservoir Rock: Layers of rock with produced Oil & Natural gas received through the migration pathway

- Cap Rock: Layer above reservoir rock preventing further vertical travel of the produced Oil & Natural gas

- Geological Trap: Horizontal trap formed with rocks and water finishing requirements for a perfect Hydrocarbon system with light dense Natural gas trapped at the top and Oil beneath it.

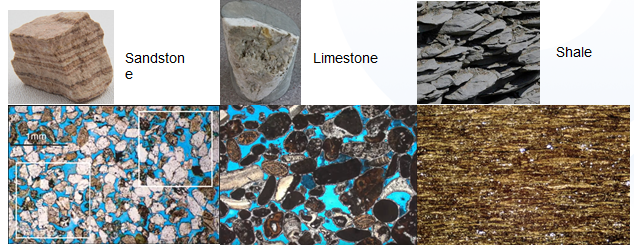

Reservoir Rocks

Permeability and Porosity defines an efficient reservoir rock, there are 3 types of those:

Sandstone & Limestone otherwise called as ‘Conventional reservoir rocks’ with high porosity and permeability whereas Shale (made of Silt and Clay) called as ‘Unconventional reservoir rocks’ with relatively low porosity & permeability making economical extraction a challenging task for the investors.

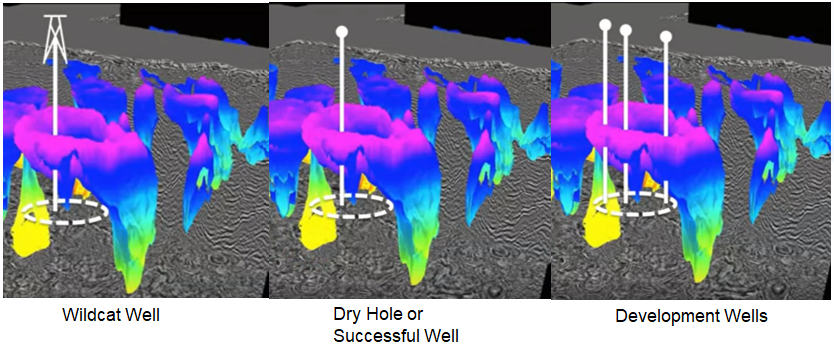

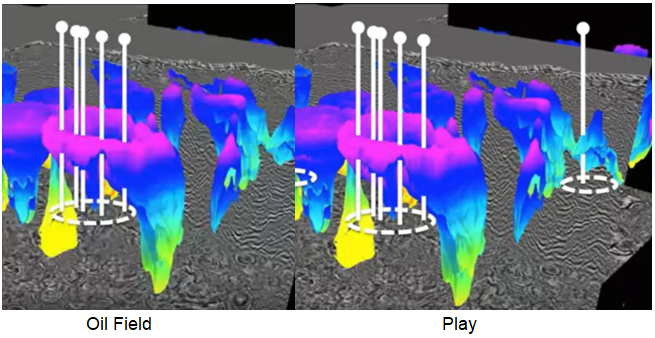

Prospect to Play

Without going into much detail on identification of prospects, Geologists based on the satellite data and seismic study results will create geological models for potential regions for extraction called as ‘Frontier Regions’. Once the developed geological models within the frontier region shows potential prospects of reservoirs & after further agreements between the mineral rights holder and investors, a Wildcat well will be drilled in the region.

If the Wildcat Well is successful, further development wells will be drilled to maximize the production. If unsuccessful, the wildcat well will be sealed and left as a dry hole.

Prospect to Play

Over a period of production, more and more development wells will be drilled to enhance production and the region will be called as an ‘Oil Field’. More oil fields developed within a frontier region will be further termed as ‘Play’.

This is what the Oil & Gas Industry calls, ‘Prospect to Play’

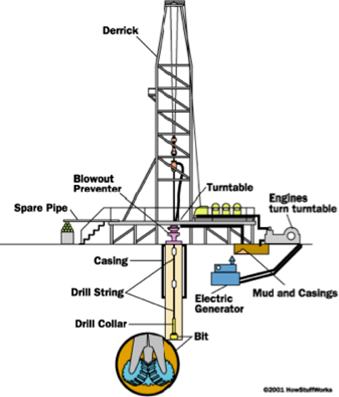

Drilling Process

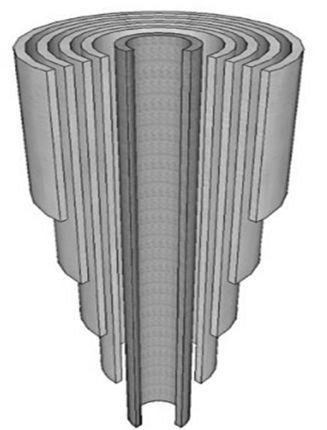

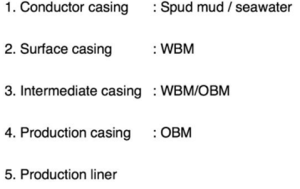

Let’s drill deep in to some technical concepts and processes of the industry, starting with the ‘Drilling Process’. Basic components required for a drilling process are a platform and a tower structure, the structural components/arrangements of a drill platform and the tower depends on the location of the drilling (whether on ground or offshore). If you ever go through a picture as shown above with complicated systems/components looks floating over a sea, you are looking at a drilling/production platform. Once the drilling platform and the tower structure are in place, next phase of drilling is to place Conductor Casing and pumps to circulate mud. Conductor casing acts as further pathway to next set of casings (lesser in diameters) and supply of mud performs 3 important role in the drilling process. 1. Acts as a lubricant for the drill bit 2. Acts as a carrier to remove cut rocks from the drill chamber 3. Acts as a barrier to prevent any pressurized fluids from the drill zone to escape out.

Drilling Process

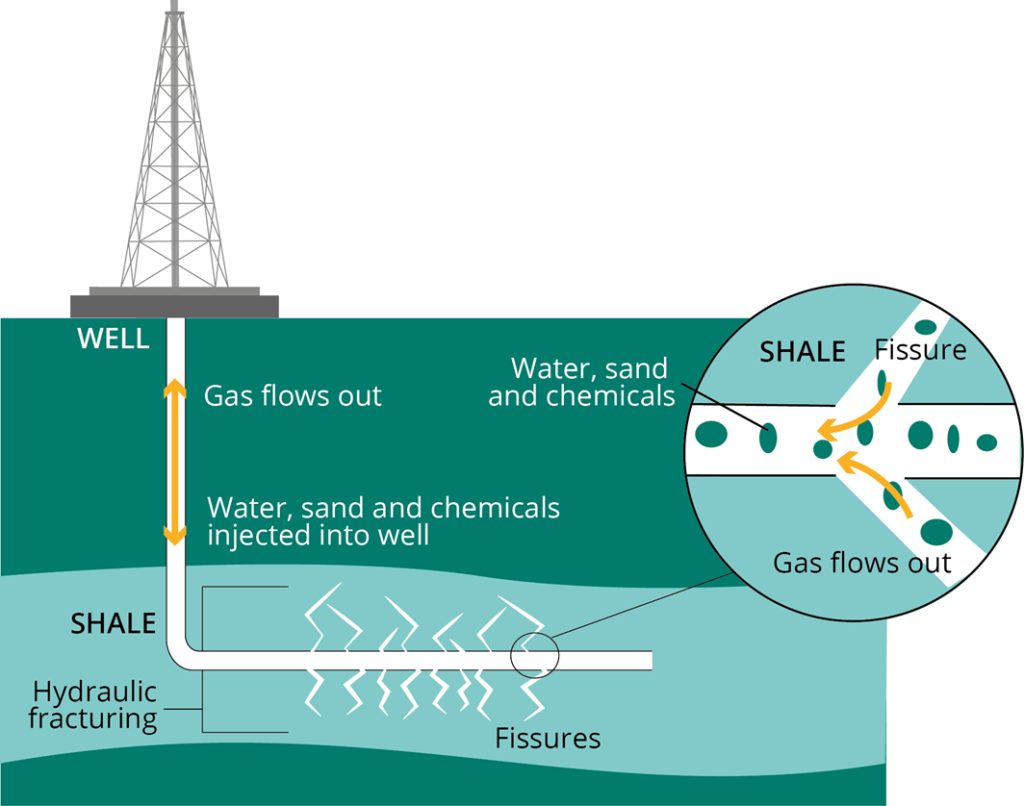

Surface casing will be then placed to prevent ground water to enter into the drill zone and the produced fluid from contaminating the ground water table. A Blowout preventer will be then installed before further drilling. Once conductor casing, surface casing, mud supply system and blow out preventer are installed, the platform will be ready for further drilling. Vertical drilling will be continued to the depths of reservoir followed with directional drilling through the reservoir zone to maximize production. Directional drilling is one of the key developments enhancing economic feasibility of Oil & Natural gas exploration (e.g. In the picture above, without directional drilling technology the investor would be multiple vertical drilling platforms to explore the reservoir zone). Once drilling is completed, production casing will be laid and sealed. Then a penetrating gun will be injected through the production casing and will initiate series of blasts at various portions within the reservoir zone. Fluids stored in the reservoir rocks at a high pressure will then eventually flow towards the surface through production casing initiates Oil / Natural gas production. Technique called as ‘Hydraulic Fracturing or Fracking’ will be then applied to maximize production which is further explained under Enhanced Oil recovery section in this presentation.

Production over Time

Uff!! Lots of technical details and theories, I understand you might have started getting bored at this point. I have tried making the next portion interesting with some graphs and discussions. Assume you are an investor or a mineral rights holder, Will you leave it to the reservoir pressure to decide quantity of oil/natural gas production? You will try all other legal, economical and environmental friendly ways/techniques to enhance the production over time in a well or a field, Correct? That’s the next section, Production Over Time!

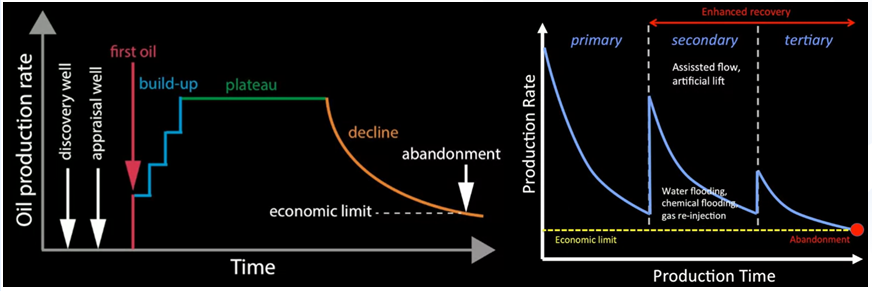

Left graph above represents oil production in a field over a period of time, from the discovery of first oil after wild cat well to abandonment. After first oil, the investor will drill further developmental wells around the region (forming an oil field) to maximize the production which will eventually reach a Plateau at some point during the production. The field after producing oil for a period of time (years & decades) will start declining and will be abandoned at a point when further extraction vs production is no longer economically feasible.

Primary production in the right graph depicts production of oil through reservoir pressure (generally 5-15%) which eventually declines when secondary and tertiary recovery methods, otherwise called as ‘enhanced recovery methods’ will be deployed which in turn assists the investor in maximizing production from a well / field.

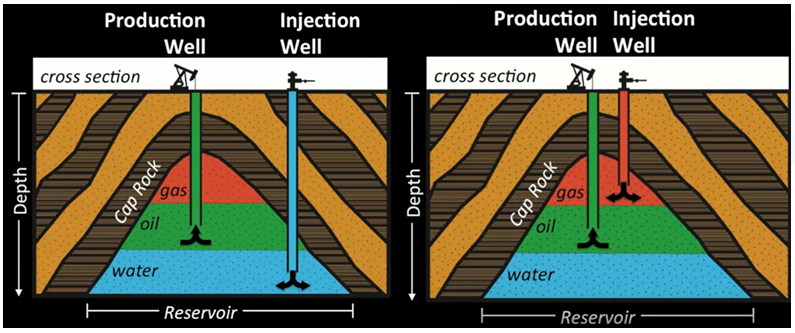

Enhanced Oil Recovery

Secondary recovery techniques involves water flooding / gas re-injection through injection wells as shown in the images above. Natural gas being less dense than oil and water will be trapped (below cap rock) above both the layers in the geological system. The idea here is flooding produced water (to the water layer) through injection wells pushing Oil to move into the production casing. Alternatively, injecting produced natural gas (to the gas layer) compressing oil to move into the production casing. In both of the above techniques, no direct injections / additions in to Oil layer which is then used in the tertiary recovery process.

Tertiary recovery process involves addition of certain chemicals directly to the oil layer which helps increasing the viscosity (acts like a soap) which in turns maximizes flow into the production casing.

Processing Natural Gas

The next process after recovery of Oil / Natural gas is ‘Processing or Refining’ since the produced oil & natural gas has impurities / other elements making it not immediately ready for domestic / industrial applications. Get ready for more technical stuff in the upcoming slides!

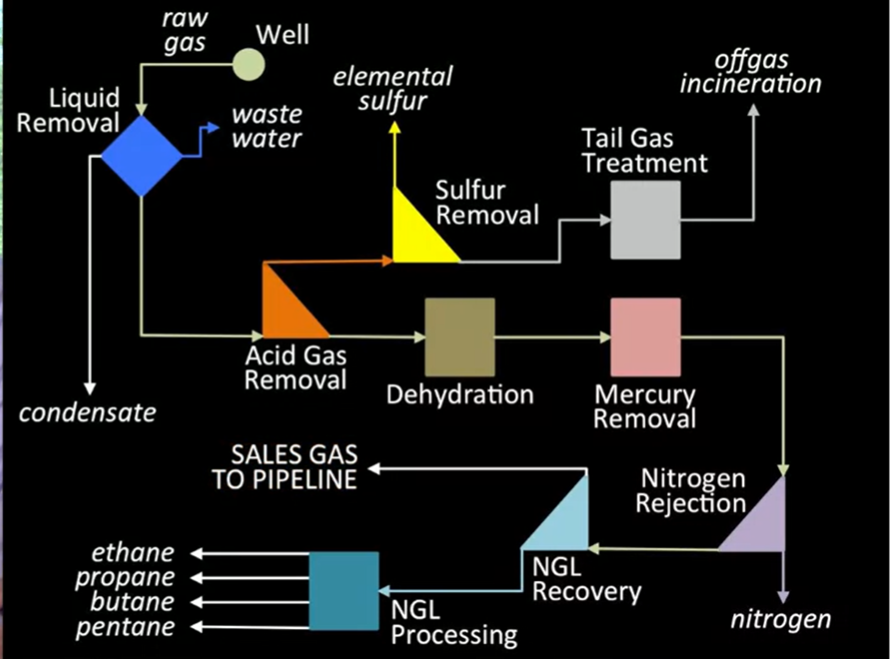

We will start with a Natural Gas refinery / processing plant. Raw gas from a well will first undergo deliquification removing waste water and condensate. Condensates are heavy hydrocarbons which will be further processed in Oil / other refineries. ‘Liquid removed’ natural gas will then undergo Acid removal which will produce elemental sulfur and tail gas as by products. Sulfur will be then used for other applications and tail gas can be incinerated to generate energy.

After dehydration, mercury removal and nitrogen rejection the Natural gas (dry gas) will be ready to go mid-stream and downstream domestic / industrial applications. If the refined gas is wet gas instead, it will include Natural Gas Liquids (NGLs) with low hydro carbon structures like ethane, propane, butane and pentane which will be then recovered for other applications. Above processes represents Natural gas refining on a brief.

Processing Oil

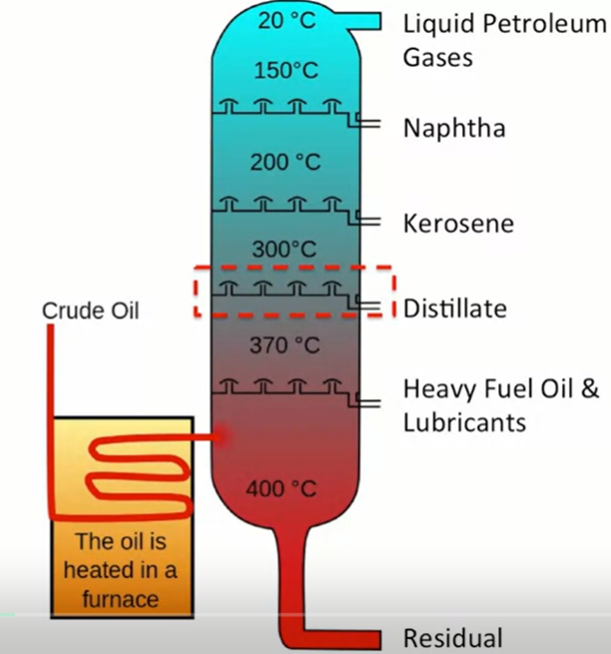

I remember above picture from my high school Physics book, Fractional Distillation!! Yes, Fraction Distillation chamber is the heart of any Oil Refinery in the world. The key idea of an oil refinery is to decompose long chains of hydrocarbon structures in the Crude oil into variety of low chain hydrocarbon structures which in turn produced into multiple applications.

Vaporized crude oil will be circulated from the bottom of the distillation chamber which will be then cooled to the ambient temperatures at the top of the chamber. Throughout the process, hydrocarbon systems with varying boiling points precipitates out at different levels.

From the top, ‘Liquid Petroleum Gases’ with lowest boiling points precipitates out at the top which will be then compressed in containers used as stoves. Next hydrocarbon element to precipitate out from the chamber are ‘Naphthas’. Naphthas are raw material or Gasoline (the primary fuel used in US), synthetic rubber, petro-chemicals and all other plastic products. Precipitates even down in the Chamber are more heavier petro-chemicals named ‘Kerosone’ primarly used as jet-fuel. Following Kerosene, the Distillates are further processed and used as Diesel (primary fuel in Europe and India). The last element to get precipitated from the distillation chamber is ‘Heavy Fuel Oil & Lubricants’ used as Bunker Fuel in ships and lubricants in industrial processes. Further down in the chamber lies residual crude oil with longer hydrocarbon chains with more than 25 carbon atoms which will be further processed to Asphalt and Bitumen.

Processing Oil

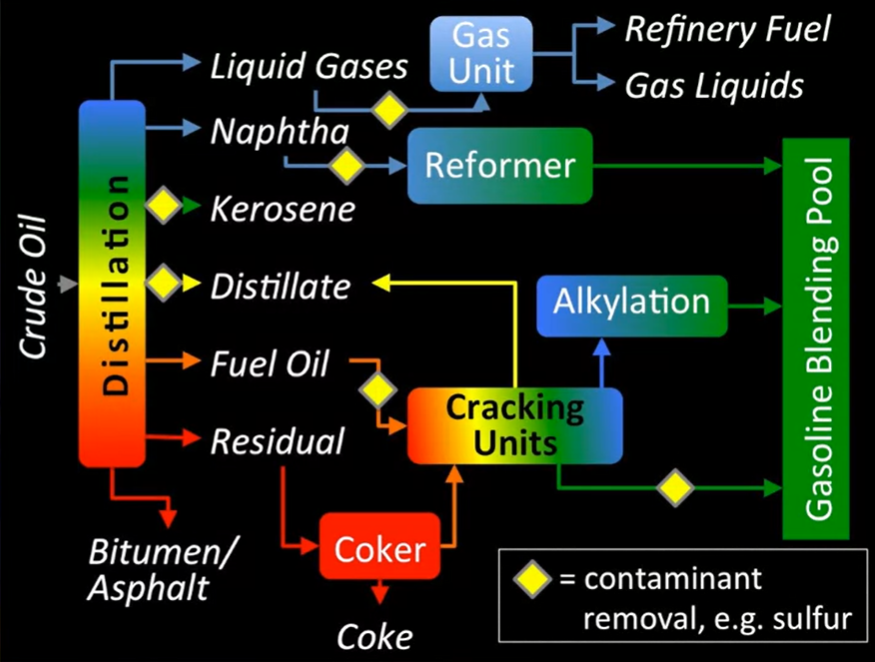

Based on the targeted end use and profit maximization in-line with market demands, various refining / processing units are deployed within an oil refinery plant. For example if the customer is US with more demand towards Gasoline, processing units will target breaking-down or combining-up hydrocarbon chains to produce Naphthas which is a primary raw material to produce Gasoline and in the case of Europe, the target would be to generate more Distillates which in turn to produce Diesel.

Cracking Units breaks long chains of distillates into shorter chains of gasoline fuels (Alkylation adds Octane value of the fuel), whereas the Reformers unifies low octane naphthas into high octane longer chain gasoline molecules. Coker or Coking Units processes high viscosity crude oil (with the exception of Bitumen & Asphalt) into low carbon chains which in turn can be further processed in Cracking units. Coking units produces a key by-product called as Petroleum Coke which is used in high temperature process plants like Steel Manufacturing.

In addition to the above, an advanced refinery will include a gas processing unit and contamination removal chambers adding these up to storage tanks and pipes to move fluids around you will end-up with a massive scale processing plant almost in a size of a small industrial town.

Processing Oil

Images show Cracking Unit, Reformer and Coking Units in the order of left to right.

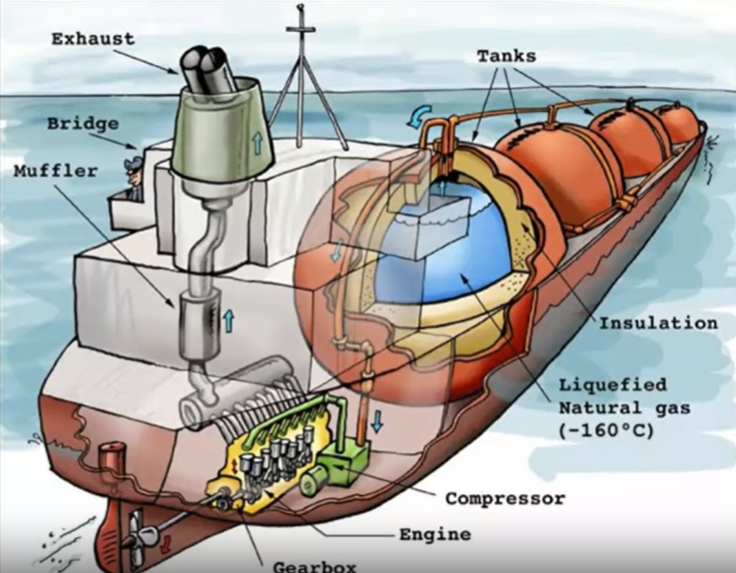

Liquefied Natural Gas (LNG)

We will finish this presentation covering basics of Liquefied Natural Gas (LNG) which is one of the key export from Qatar. There is an increasing demand for Natural Gas because its more cleaner and environmental friendly comparing to the Crude oil products. Liquefaction of Natural gas is a complex process which involves massive plants (often called as Liquefaction trains because of its Train like structure) which removes impurities from the Natural gas and super-cool it to temperatures less than -161 C (i.e. Boiling point of the Natural gas). Liquefied Natural Gas (LNG) will be then transported through specifically designed carriers to the destined location and then gasified back to Natural gas for domestic / industrial applications.

I believe the information presented above gave a basic understanding of the production & processing of Oil & Natural gas industry. Based on your feedback and response, we will continue to add more detailed write-ups focusing specific elements in the Oil & Gas Industry.Conserve Solutions will be happy to assist your projects. Our offices are located in India, UAE, Qatar, Saudi Arabia, Canada, United Kingdom, Egypt and Singapore.

Author