Air terminal units such Fan Coil Units (FCU), Variable Air Volume (VAV), and Constant Air Volume (CAV) systems are essential components within centralized HVAC systems. If these equipment are not well designed and efficiently installed, it could result as a significant source of noise and thereby affecting Occupant comfort. We have analyzed in brief, the characteristics of noise transmission and generation from air terminal units along with the potential noise reduction in this article.

Air Terminal Unit Noise Generation and Transmission Characteristics

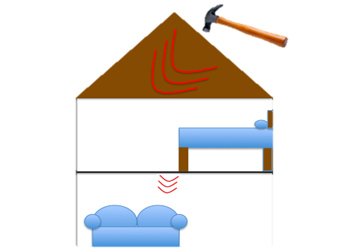

Conventional design strategy being adopted in the market is to add acoustic lining (15mm to 50mm) for the first 3 meters or up to first branch of the distribution network from the Air Termina Units. Is this strategy really solving the Acoustic intent for the Project? Understanding more on the noise generation and transmission characteristics of the HVAC system would help. Noise generated from the equipment fans and drivers is transmitted to the supply & return outlets and radiates through the casing / ducts. This noise in turn can be transmitted to the Occupant in a variety of paths, including;

- Supply and Return Transmission: Transmitted through the ducting

- Radiated Noise: Radiated directly to the receiver in an open ceiling arrangement and Attenuated through the Ceiling in a concealed system

- Aerodynamic Noise: Noise produced due to air movement through duct fittings, accessories, and air distribution terminals (Grilles, Diffusers, etc.).

Mitigation Measures

- Equipment Selection: Selecting quiet equipment will save further investments in Acoustic liners and Acoustic Ceilings.

- Equipment Location: Locate the equipment in adjacent circulation or wet areas to avoid radiated noise transmission in the Occupied rooms (e.g. Executive Offices, Guest Rooms in Hotels, Patient Rooms in Healthcare).

- Duct Cross-Section Design: Poor duct cross-sectional design increase air velocity thereby resulting in Aerodynamic noise, hence ASHRAE recommendations on Air Flow Velocities shall be followed in-line with the room’s Noise Criteria (NC) objectives.

- Location of Air Distribution Components: Place grilles, diffusers & registers away from elbows and branch takeoffs, and apply flexible connectors wherever possible between Duct path and the distribution components.

- Turning Vanes: Use turning vanes in larger elbows to avoid turbulence and associated noise generation.

- Position of Return Bell Mouth: The return bell mouth should be positioned away from the return diffusers to avoid noise transmission.

- Duct Lagging: Install duct lagging insulation to prevent duct breakout noise and condensation.

- Vibration Isolators: Use vibration isolators in equipment and duct hangers to minimize noise generation.

Conclusion

Air terminal Unit noise can be a significant source of noise pollution if not effectively managed, controlled. Mechanical Engineers should have an understanding on the noise generation and transmission characteristics and implement appropriate mitigation measures as applicable. Proper consideration of above measures into the design and construction will lead to a quieter and comfortable environment.

Related Blogs

Author

Sheik Abdullah

Sheik is an Assistant Project Manager in Acoustics Division, having completed a Bachelor's Degree in Mechanical Engineering and a Post Graduate Diploma in Acoustics & Noise Control from Prestigious Institute of Acoustics (IOA), UK. He has over 7 years of professional consultancy experience in various Engineering domains such as Acoustics, Sustainability and Building Services.