- Inspire

- Innovate

- Integrate

- Home

- Who we are

- Services

- Portfolio

- Training

Green Building Credential Courses

Classroom Courses NewLEED Green AssociateLEED AP BD+C Certification Training in Saudi ArabiaOnline Courses NewLEED Green Associate Exam Preparation CourseLEED AP BD+C Exam Preparation CourseIGBC AP Made Easy – Online Exam Preparation CourseCourse Materials NewLEED V4 AP BD C Made EasyLEED Green Associate Made Easy V4Energy Modeling & Simulation CourseLEED and IGBC Exam Preparation – Q&A forum NewEngineering Courses

- MEP Engineering Training Course Qatar New

- Fire Fighting New

- Plumbing Training Course with Certification New

- Heating Ventilation & Air-conditioning New

- 3D laser Scanning Training Course Qatar New

- Electrical Design Course

- Piping Design course – Piping Simulation Analysis Training

- Energy Modeling & Simulation Course

- Blog

- Careers

- Contact Us

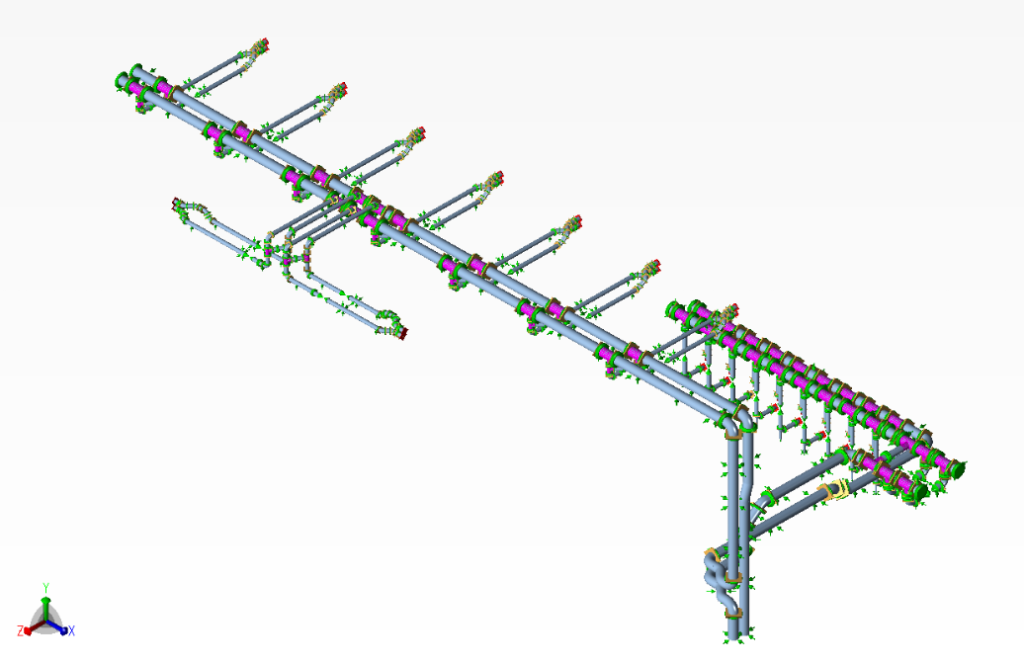

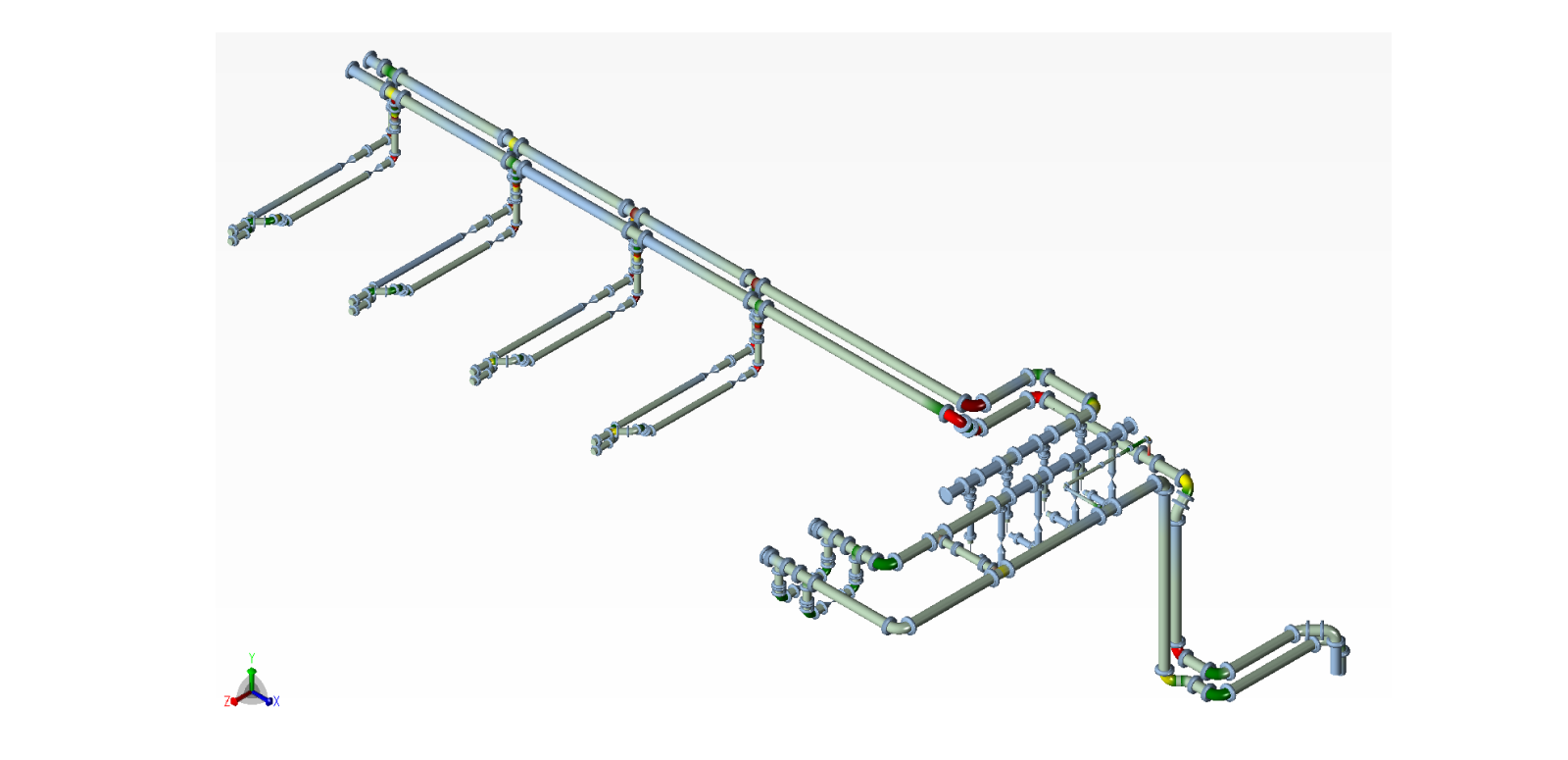

At Conserve Solutions, our commitment is to deliver exceptional Piping Stress Analysis services, supported by a wealth of professional experience

What is Piping Stress Analysis?

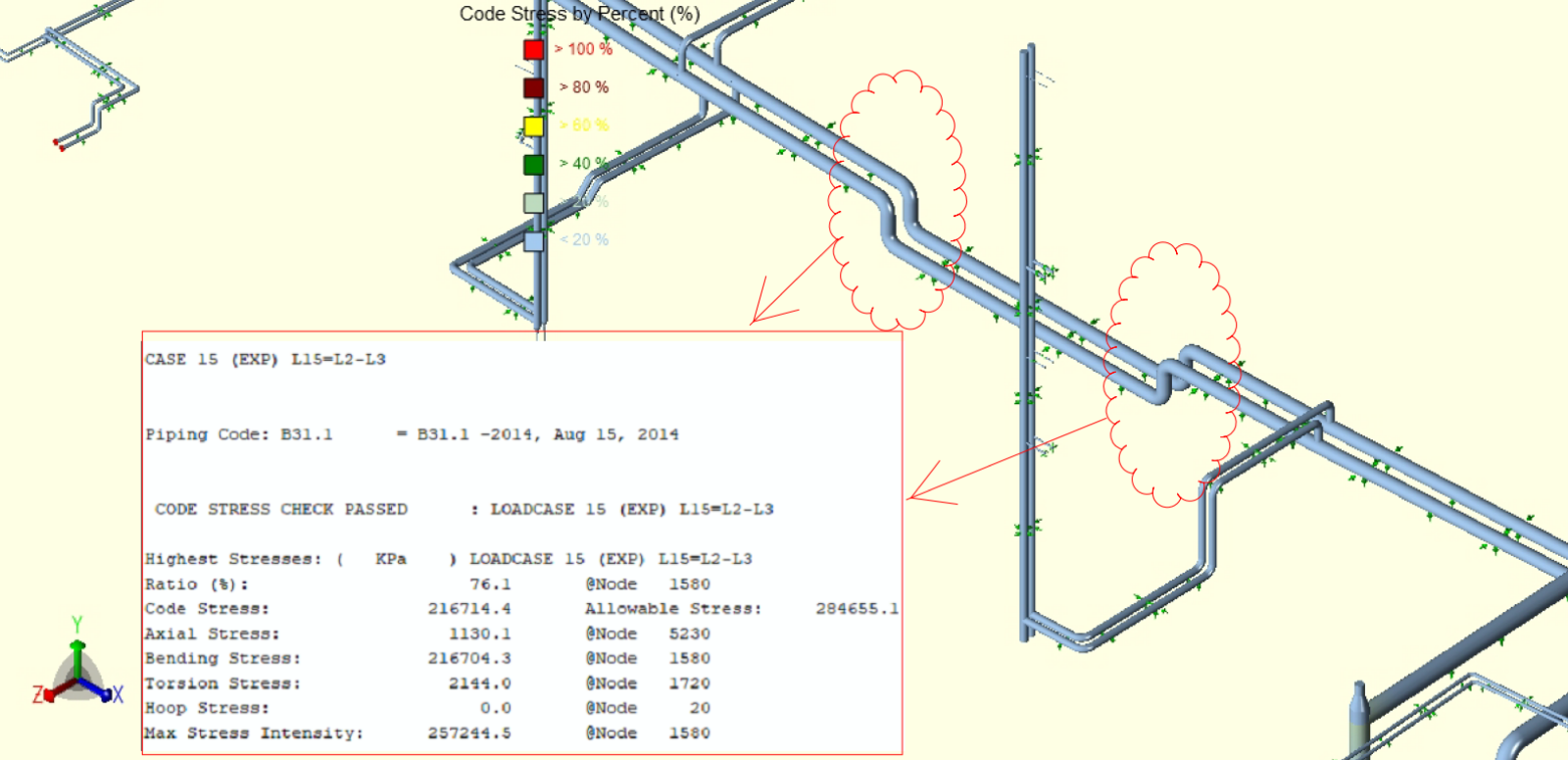

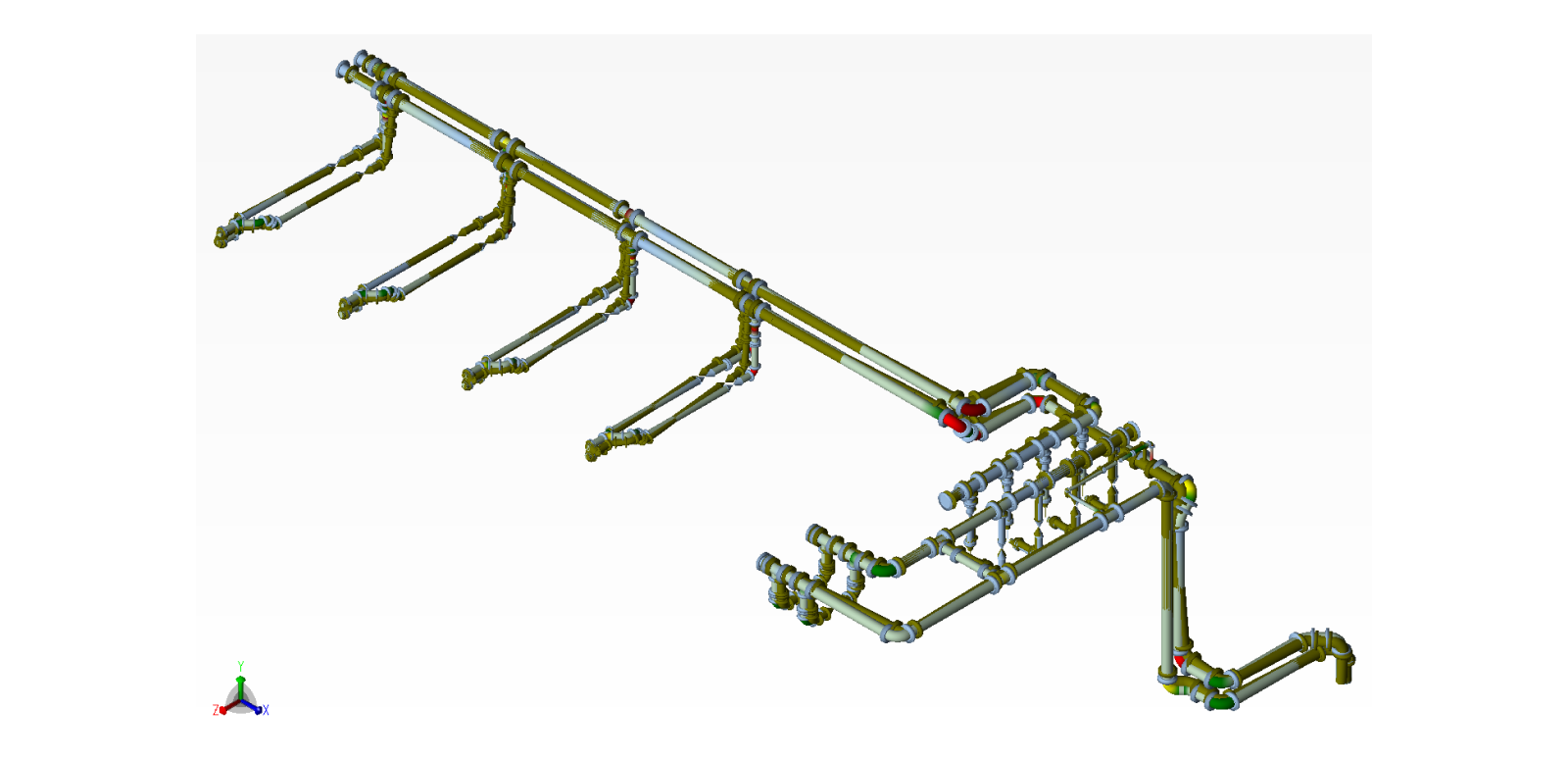

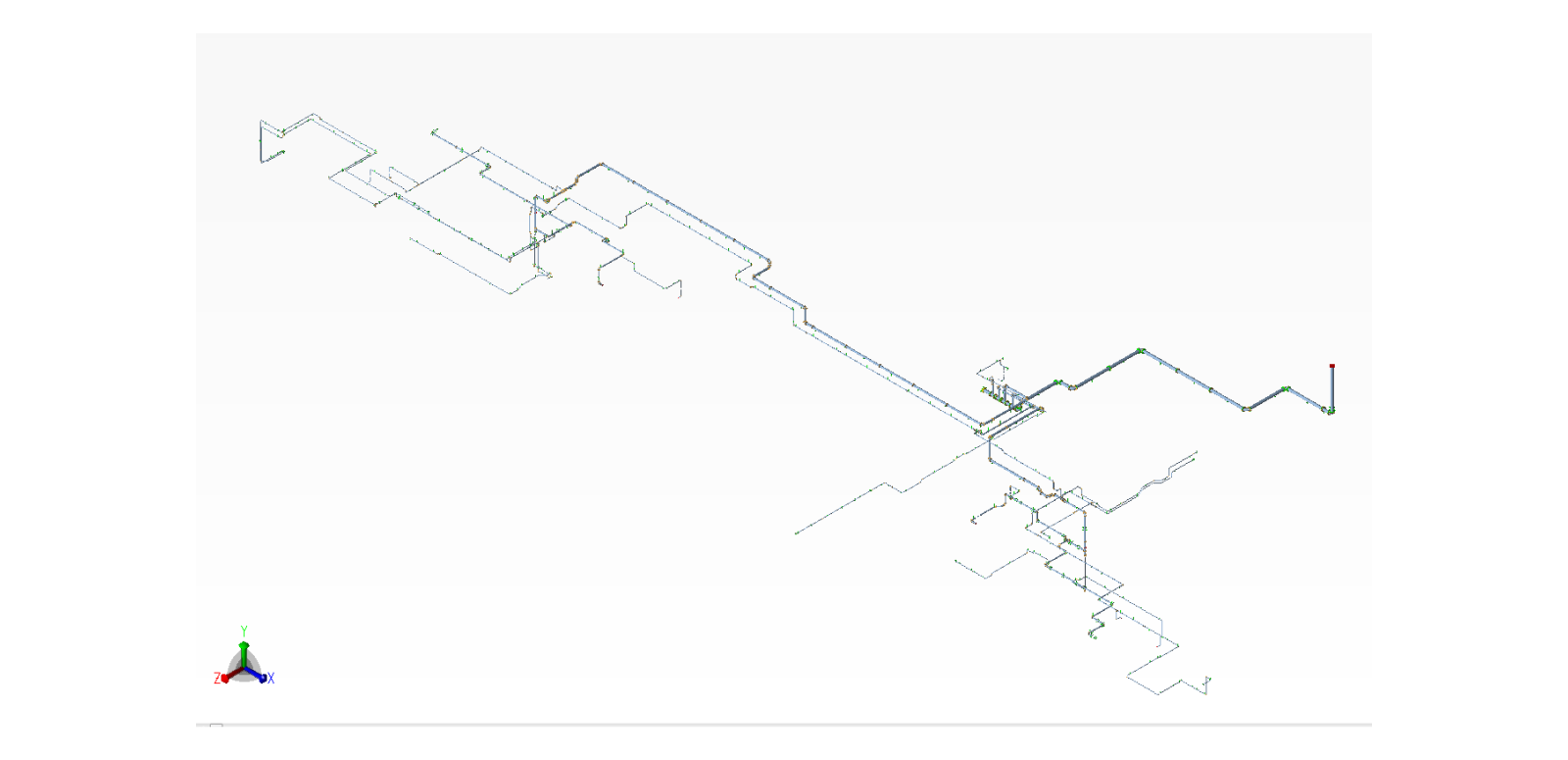

Piping Stress Analysis, often referred to simply as Stress Analysis, is a critical engineering discipline in the field of mechanical and structural engineering. It involves the assessment of how various forces, pressures, temperatures, and external loads impact the integrity and performance of a piping system. The primary goal of Piping Stress Analysis is to ensure that the pipes, fittings, and supports in a system can withstand these stressors without experiencing excessive deformation, failure, or compromising safety.

We Provide a Wide Range of Piping Stress Analysis

Modal analysis

Harmonic analysis

Vibration analysis

Vibration analysis

Time–history analysis

Water hammer analysis

Equivalent Static analysis (Dynamic)

Pressure loading

Occasional loading

Thermal loading

“Output of analysis is provided in the form of report and animations containing profiles of the required parameters at different planes for the review & approval of the clients/AHJ”

Our Tools Used for Stress Analysis

CAESAR II, by Hexagon

Auto pipe, by Bentley

CAEPIPE, by SST USA

PEPS, by DST Engineering

Rohr2, by Sigma, Germany

PASS/START-PRO

Why Choose

Conserve Solutions?

Expertise and Experience

Our team comprises seasoned professionals with extensive experience and in-depth knowledge in the field of piping stress analysis.

Customized Solutions

We recognize that every project is unique, and our approach reflects this understanding. Our services are tailored to meet your specific requirements and goals, whether it involves optimizing designs, enhancing efficiency, or ensuring the safety of your piping systems.

Dedication to Excellence

At Conserve Solutions, our commitment to delivering high-quality piping stress analysis services is unwavering.

Comprehensive Analysis

We employ advanced tools and methodologies to conduct comprehensive stress analyses on your piping systems, identifying potential issues and recommending solutions to enhance performance and reliability.

Frequently Asked Questions

FAQ's

Piping stress analysis is an engineering evaluation that assesses the impact of various forces, pressures, and temperatures on piping systems. It’s crucial to ensure the structural integrity, safety, and reliability of these systems, especially in industries like oil and gas, petrochemicals, and power generation.

Piping stress analysis should be considered during the design and engineering phase of a project, whenever modifications are made to existing systems, or if there are concerns about the integrity and performance of the piping.

Piping systems can experience various stresses, including thermal stresses from temperature fluctuations, pressure-induced stresses, weight and gravity-related stresses, and vibration-induced stresses.

Piping stress analysis helps optimize designs, prevent failures, enhance system efficiency, and ensure safety compliance. It ultimately reduces the risk of costly downtime and maintenance.

The timeline for a piping stress analysis can vary depending on the complexity of the system and the specific project requirements. It’s best to consult with your service provider for an estimate.

Get in Touch

Have Any Other Questions?

Technical Samples

Subscribe

Get latest news & events details

Quick Links

+1 (832) 475-9130

+44 0786 7249154

+91 73059 60692

+91 96772 63895

+65 8709 8733

+966 55 720 9522

+974 44427968

+971 45657706

Copyrights © 2025. Conserve Solutions. All Rights Reserved.