- Inspire

- Innovate

- Integrate

- Home

- Who we are

- Services

- Portfolio

- Training

Green Building Credential Courses

Classroom Courses NewLEED Green AssociateLEED AP BD+C Certification Training in Saudi ArabiaOnline Courses NewLEED Green Associate Exam Preparation CourseLEED AP BD+C Exam Preparation CourseIGBC AP Made Easy – Online Exam Preparation CourseCourse Materials NewLEED V4 AP BD C Made EasyLEED Green Associate Made Easy V4Energy Modeling & Simulation CourseLEED and IGBC Exam Preparation – Q&A forum NewEngineering Courses

- Robotics -for Little Engineers New

- MEP Engineering Training Course Qatar New

- Fire Fighting New

- Plumbing Training Course with Certification New

- Heating Ventilation & Air-conditioning New

- 3D laser Scanning Training Course Qatar New

- Plumbing & Fire Fighting

- Electrical Design Course

- Piping Design Engineering Training Course

- Piping Design course – Piping Simulation Analysis Training

- Energy Modeling & Simulation Course

- Blog

- Careers

- Contact Us

- Home

- Tarsheed Solutions Engineering Consulting Company

- Simulation & Analysis Services

Simulation & Analysis Services

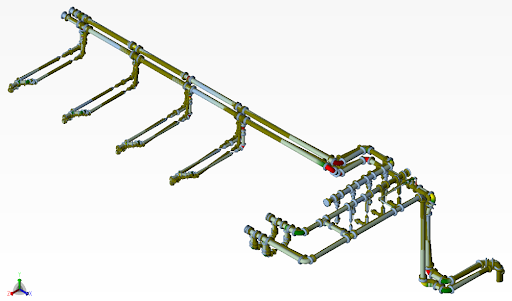

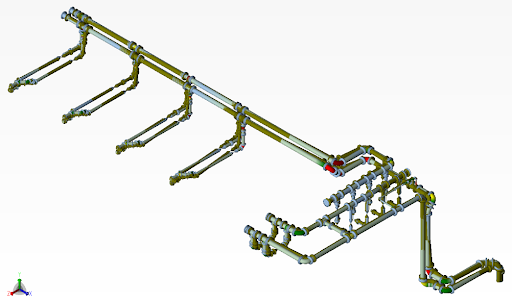

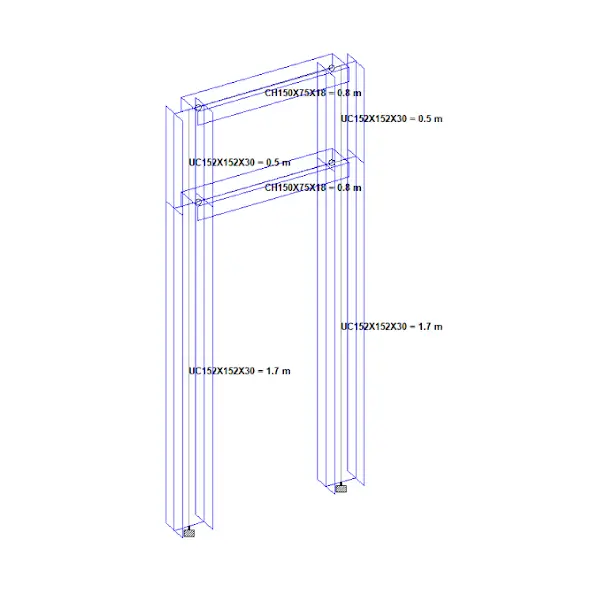

Conserve offers its specialized Simulation & Analysis services in the Kingdom of Saudi Arabia. Simulation & Analysis is based on Finite Element Analysis (FEA) concepts & methodologies carried out to foresee the behavior of Building/Industrial systems. Outcomes from these analyses are widely used to understand load/stress distribution across piping networks and designing suitable support structures to avoid potential future failures. Conserve offers wide range of FEA analysis services includes,

- Pressure Vessel Analysis

- Thermal Analysis

- Flow Assurance Analysis

- Cooling Tower and Chiller Yard Analysis

- Root Cause Analysis

- Slug Analysis for Oil & Gas

- Mixture and Agitator Design Analysis

- Support Design and Analysis

- Stress Analysis

- Surge Analysis

- Seismic Analysis

- Vibration Analysis

- Computational Fluid Dynamics (CFD) Analysis

- Pulsation Analysis

- Hydraulic, Pump Head Calculations

- Finite Element Analysis

Codes and Standards

- Air Cooled Heat Exchanger: API 661

- Fired Heaters: API 560

- Flat Bottom Welded Storage Tanks: API 650

- Heat Exchangers: TEMA/ Vendor-Specific.

- Vessel/Column: Vendor-Specific/ ASME Sec VIII

- ASME B 31.4/ASME B 31.8: Pipeline Stress Analysis

- ISO 14692: GRE/GRP/FRP Piping Stress Analysis

- ASME B31.3: Process piping Code

- ASME B31.1: Power Piping Code

- Centrifugal Pumps: API 610

- Positive Displacement Pumps: API 676

- Centrifugal Compressors: API 617

- Reciprocating Compressors: API 618

- Steam Turbines: NEMA SM23/ API 612

Applications

- Storm Water Network

- Wastewater Network

- Boiler Network

- Oil & Gas Networks

- Underground Infrastructure Network

- Chilled Water Network

- Condenser Water Network

- Low Temperature Hot Water Network

- Fire Fighting Network

- Potable Water Network

Stress Analysis

Key objective of performing stress analysis is to ensure structural & operational integrity of the piping system, which derives outcomes such as critical spots in the network and proposed support design to ensure adequate flexibility. Based on the project requirements, we shall carry out,

Static Stress Analysis (Considering Sustained, Hydro-test, Thermal Expansion Conditions)

Dynamic Stress Analysis (Considering Seismic, Vibration, Water Hammer and Slug Conditions)

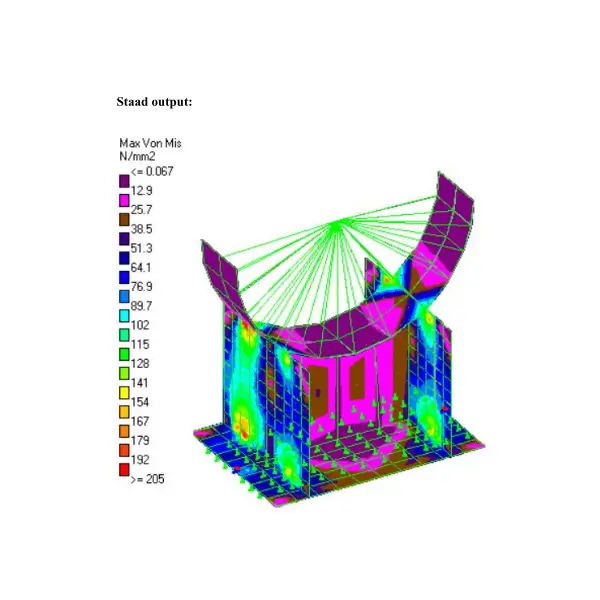

Support Design

Based on outcomes from above explained Stress Analysis, Conserve’s structural team shall design proposed support system ensuring efficient support distribution for the network. Some of the major support configurations as follows,

- Constant Spring Hanger: Flexible support, Act as Rest support allowing thermal displacements.

- Rigid Hanger: Hanging support from the top.

- Struts: Dynamic Restraint

- Snubbers: Dynamic Restraint

- Sway Braces, etc.

- Rest Support: Restrict downward movements.

- Guide Support: Arrest lateral movements.

- Line Stop or Axial Stop: Restrict axial or longitudinal movement of the pipe.

- Anchor Support: Completely fixed. Restrict all six degrees of freedom. Pipe at this support point can’t translate or rotate.

- Variable Spring Hanger Support: Flexible support, Act as Resting support with flexibility to thermal movements.

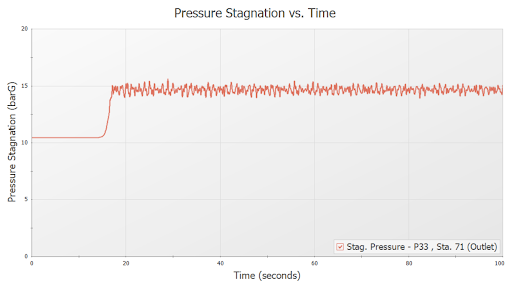

Surge Analysis

Surge shall occur in any piping network due to sudden modifications in velocities of flowing fluid, often called as Water/Fluid Hammer or Hydraulic Surge. Surge Analysis is transient carried out under following scenarios,

- Pump Start-up Condition.

- Pump Trip Condition.

- Sudden Valve closure condition.

Conserve shall analyze piping network and propose optimum engineering solutions to avoid/overcome potential surges within the network.

Subscribe

Get latest news & events details

Quick Links

+1 (832) 475-9130

+44 0786 7249154

+91 73059 60692

+91 96772 63895

+65 8709 8733

+966 55 720 9522

+974 44427968

+971 45657706

Copyrights © 2025. Conserve Solutions. All Rights Reserved.