How Critical Infrastructure Projects Control Noise Without Compromising Operations?

Introduction

High-noise equipment rooms, such as generator rooms, pump rooms, and mechanical plant spaces are unavoidable in modern infrastructure. What is avoidable is allowing that noise to spill into occupied or sensitive areas.

Box-in-Box acoustic design is one of the most effective engineering solutions for isolating airborne and structure-borne noise in such environments. When designed correctly, it delivers high noise reduction without disrupting surrounding operations, especially in dense urban and mixed-use developments.

This article explains what Box-in-Box design is, how it works, where it’s used, and why it matters for infrastructure projects that demand acoustic control without compromise.

Table of Contents

- What is Box-in-Box Acoustic Design

- Where Box-in-Box Is Applied

- How Box-in-Box Works (Design Methodology)

- Key Engineering Components

- Benefits of Box-in-Box Design

- Challenges and Design Implications

- Practical Example: Equipment Room Inside an Occupied Facility

- Why Choose Conserve Solutions

- Conclusion

1. What is Box-in-Box Acoustic Design?

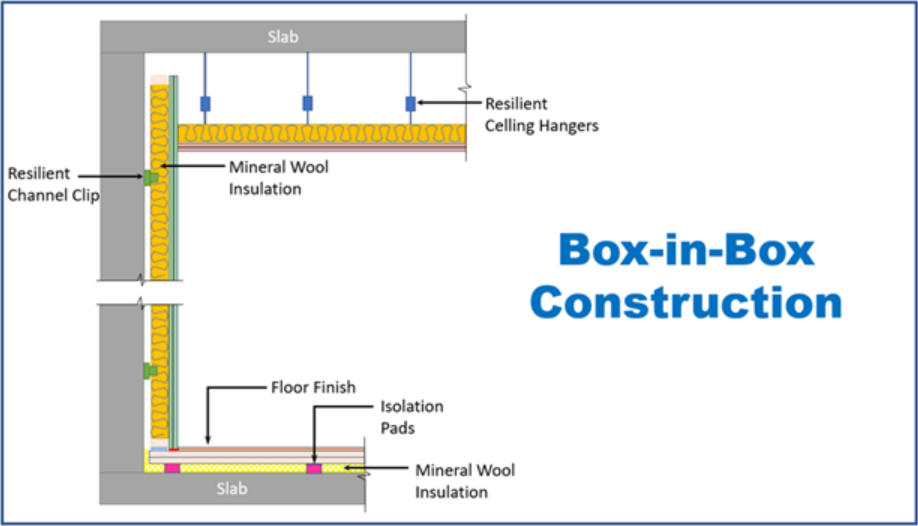

Box-in-Box design is an acoustic isolation strategy where a noise-generating space (inner box) is structurally separated from the surrounding host building (outer box).

Instead of relying on thicker walls or localized treatments, this method creates a physically decoupled enclosure that significantly limits:

- Airborne noise transmission

- Structure-borne vibration transfer

- Noise leakage through weak elements

In simple terms:

- The noisy room is built as an independent structure inside another structure.

2. Where Box-in-Box Is Applied

Box-in-Box design is commonly used in high-noise, mission-critical environments, including:

- Generator rooms

- Machine rooms

- Chiller and HVAC plant rooms

- Pump rooms

- Industrial equipment enclosures

Typical scenario:

A generator room constructed inside a parking structure or basement adjacent to offices, residences, or control rooms.

3. How Box-in-Box Works (Design Methodology)

The effectiveness of Box-in-Box design depends on system thinking, not individual materials.

Step-by-Step Design Logic

- Step 1: Structural Separation

The inner enclosure is isolated from the surrounding building to prevent vibration transfer. - Step 2: High-Mass Inner Construction

Walls, ceilings, and floors of the inner box are designed with materials that provide high sound reduction across frequencies. - Step 3: Internal Sound Absorption

Sound-absorbing materials line the inner surfaces to control reverberation and reduce internal noise buildup. - Step 4: Control of Acoustic Weak Points

Doors, ventilation ducts, penetrations, and service openings are treated as critical risk zones. - Step 5: Isolation of Structure-Borne Sound

Equipment, pipes, and ducts are mechanically isolated using resilient connections and vibration control elements.

Each step reinforces the next. Skipping one weakens the entire system.

4. Key Engineering Components

Inner Box Construction

- High-density walls with high sound reduction index.

- Typical configuration: solid wall + drywall lining system.

Sound Absorbing Linings

Installed on inner surfaces to:

- Reduce reverberant noise buildup

- Lower exposure levels for operating personnel

- Improve overall isolation effectiveness

Doors and Openings

- Acoustically rated doors

- Full perimeter sealing

- Minimal and tightly controlled penetrations

Ventilation & Ducting

- Acoustically lined ducts

- Sound attenuators

- One or two 90-degree bends to block direct noise paths

Structure-Borne Isolation

- Equipment mounted on isolation pads

- Resilient channel clips for walls

- Resilient ceiling hangers

- Flexible connectors for pipes and ducts

5. Benefits of Box-in-Box Design

- High Noise Reduction – Achieves significantly higher sound isolation compared to conventional wall treatments.

- Protection of Occupied Spaces – Ensures compliance with noise criteria in offices, residences, and sensitive environments.

- Improved Working Conditions – Internal absorption reduces reverberation, lowering noise exposure for operators.

- Predictable Acoustic Performance – When engineered correctly, results are measurable and reliable.

6. Challenges and Design Implications

Box-in-Box design is powerful—but not casual.

Key Considerations

- Reduced accessibility if space planning is poor

- Ventilation and cooling become more complex

- Increased space requirements

- Higher initial cost compared to basic treatments

Reality Check

This system demands precision engineering. Poor detailing at even one penetration can compromise the entire acoustic performance.

7. Practical Example: Equipment Room Inside an Occupied Facility

In a mixed-use infrastructure project, a high-capacity generator room was located adjacent to occupied operational areas.

Challenge:

Control noise without relocating the equipment or impacting surrounding spaces.

Solution:

A fully isolated Box-in-Box enclosure with:

- Independent inner walls and ceiling

- Acoustically treated ventilation paths

- Vibration-isolated equipment and services

Outcome:

- Significant reduction in transmitted noise

- Compliance with project acoustic criteria

- Safe, comfortable working conditions for personnel

8. Why Choose Conserve Solutions?

At Conserve Solutions, Box-in-Box design is not treated as a construction detail—it is approached as an integrated acoustic engineering system.

What Sets Us Apart

- Deep understanding of airborne and structure-borne noise behavior

- Coordination between acoustics, MEP, and structural design

- Attention to detailing at penetrations and weak points

- Design validation through engineering analysis, not assumptions

We engineer for performance, durability, and operational practicality—not just drawings.

Conclusion

Conclusion

Box-in-Box acoustic design remains one of the most effective solutions for isolating high-noise equipment in infrastructure projects. Its success, however, depends entirely on engineering rigor, detailing precision, and system-level thinking.When designed and executed correctly, it delivers measurable noise control without compromising building functionality. For projects where noise is non-negotiable, Box-in-Box is not an option—it’s a necessity.

Author

-

An acoustic engineer and project coordinator with over 2.5 years of experience in the acoustics field played a pivotal role in providing acoustic consulting services for over 50 projects across various sectors, including hotels, residential buildings, industrial plants, and airport terminals. His primary goal is to provide effective and feasible acoustic solutions to consultants and contractors in the AEC industry.