- Inspire

- Innovate

- Integrate

Project

Refinery Plant Project - India

Location

India

Status

Completed

Project Category

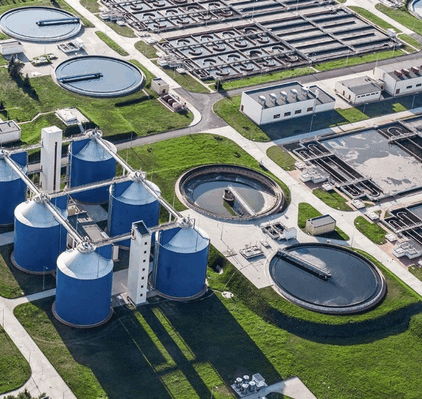

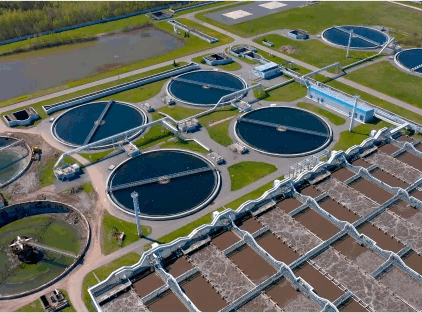

Onshore Facility

Scope of Work

Stress Analysis for Critical Piping Systems – Simulation and Analysis

Project Summary

This major expansion initiative aims to enhance the refinery’s capacity to produce cleaner, high-value fuels by increasing crude processing capability from 15 to 25 million tonnes per annum. Conserve carried out comprehensive piping stress analysis for 60 critical systems. This major expansion initiative aims to enhance the refinery’s capacity to produce cleaner, high-value fuels by increasing crude processing capability from 15 to 25 million tonnes per annum.

Our scope of work included updating stress-critical line lists, system modeling using CAESAR-II (v12 SP2), and performing detailed static and dynamic analyses. Conserve’s team verified nozzle loads, assessed trunnion strength, optimized pipe support locations, and prepared detailed stress reports, incorporating finite element (FE) analysis using NozzlePRO and FEPIPE where required. The assignment also covered preparation of requisition datasheets and vendor document reviews for specialty components such as springs, snubbers, struts, and expansion joints.

Through meticulous analysis, advanced simulation, and strict adherence to design codes and safety standards, Conserve ensured that all critical piping systems within the Refinery expansion met the highest levels of reliability, safety, and operational integrity.