- Inspire

- Innovate

- Integrate

Project

Water Treatment Plant Project

Location

New Zealand

Status

Completed

Project Category

Water Treatment Plants

Scope of Work

- General Arrangement & Plot Plans: 2D/3D plant layouts, optimized space, process flow, accessibility, safety, and regulatory compliance

- Civil & Structural Engineering: Equipment foundations, skids, structural steel, platforms, stairs, ladders, handrails; detailed fabrication drawings

- Piping Design & Engineering: 2D/3D layouts, isometrics, spool drawings, pipe supports, on-skid/off-skid MTOs

- Skid Engineering (Pump, UF-RO & Utility Skids): 3D modeling, fabrication drawings, piping, valves, instrumentation, tanks, pumps, BOMs

- 3D Modeling & Review Stages: Model development at 30%, 70%, 90%, 100%; multi-discipline integration, clash detection

- Instrumentation & Control (I&C): I/O lists, instrument layouts, cable routing (2D/3D), hook-ups, BOMs.

- Electrical Engineering: Load lists, SLDs, power & earthing layouts, lighting/socket design, cable sizing, tray routing, support/fabrication drawings

- Lifting & Installation Engineering: Lifting calculations, arrangement drawings for safe transport and installation of modular units

- Quantities & Material Management: Consolidated BOQs, MTOs, BOMs at each design stage for accurate procurement and fabrication

Project Summary

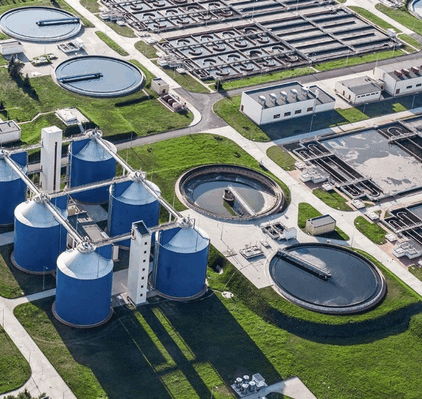

The Water Treatment Plant (WTP) project was initiated to strengthen water supply infrastructure and improve treatment efficiency. The plant plays a critical role in supporting regional water security, particularly for industrial and community needs.

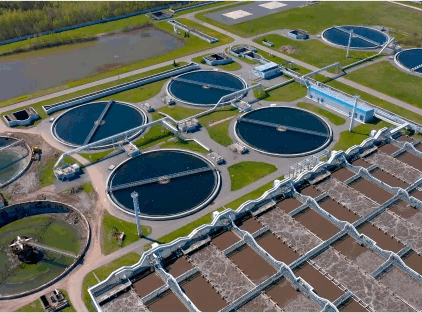

Conserve was engaged to deliver multi-disciplinary detailed engineering and 3D modeling services, encompassing multiple disciplines — mechanical, piping, structural, electrical, and instrumentation & control. The scope included updating the 3D model, preparing piping GA and isometric drawings, developing Skid GA and P&ID updates, and generating structural drawings for the UF and RO systems.

By leveraging advanced modeling and coordination techniques, Conserve ensured seamless integration of process, structural, and utility systems. The project was executed in strict compliance with client specifications and international standards, resulting in accurate, constructible designs that enhanced the plant’s performance, safety, and long-term reliability.